Drone Powerline Inspection Services

Serving Pennsylvania and New Jersey for all your commercial or individual aerial inspection needs.

Drone Powerline Inspection Services

Technicians may be injured or even killed by power line inspections. They aren’t done as often. Climbing a tower is dangerous and not recommended. Drones can be used to inspect power lines more often. This allows for more frequent inspections and less power outages.

Companies do not want to be responsible for accidents and natural disasters. However, any power line inspection or telephone line inspection can be dangerous, regardless of safety precautions. Manual inspections of lines were a necessity until recently. Many high-risk inspection tasks can now be safely replaced by drone technology.

Utility Structures | Powerlines | Communication Lines | Thermal Inspection Detections | Hazard Identification

The safer, more cost-effective, and more reliable alternative to traditional inspections using linemen or helicopters is power line inspection drones. The sophisticated energy inspection drones can capture precise data over long distances. Over 25 powerline workers are electrocuted each year inspecting power lines, along with the other added dangers including strangulation and falling. Drone powerline inspections can make all of these risks virtually extinct. Drones are able to be used for everything, from solar power inspections to safety surveys on construction sites. They’re also revolutionizing power line inspection. Drones are essential for areas where physical technicians might need to risk their lives.

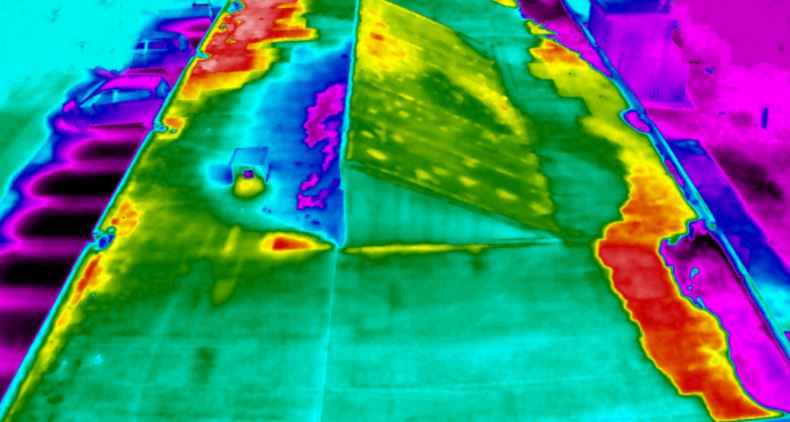

Drones can quickly map an area, navigating through power lines and avoiding towers or other hazards. Drones can cover more territory than traditional aerial vehicles because they are small and agile. They are also unmanned so they pose no danger to humans. A thermal-enabled aerial platform can help you reduce personnel risk, lower inspection costs, and complete surveys in minutes, instead of hours. Drones are the smartest option for powerline inspection.

Powerline inspection was traditionally done manually; teams would be sent to inspect assets personally, climbing poles and inspecting the lines. They would cover tens of thousands of miles each day. This may work well for utilities with smaller grids, typically between 1,000 and 2,000 km. However, for larger utilities that cover smaller distances (1,000-2,000 kilometers), this may be feasible. But it is not possible to do so efficiently without a small army of workers. Power line inspections can be time-consuming and potentially dangerous for technicians. They are not done as often. It is dangerous to climb a tower and it is not recommended. Drones allow for more frequent power line inspections. This results in less power outages and more consistent results.

Drones can be used for more than just inspections. They can be used to scan and survey the locations of potential powerlines, as well as to make 3Dmodels and simulations for future installations. To ensure that development and installation of power lines goes smoothly, they can be used. They can also be used to inspect power equipment and facilities. Drones are used to inspect transmission towers and power lines. This reduces the chance of getting hurt. Drones are safer, more efficient, and cost-effective. Drones can capture precise data from long distances and make it less dangerous than manual inspections that are sometimes dangerous. Drones are the smartest option for powerline inspection.

A thermal-enabled aerial platform can help you reduce personnel risk, lower inspection costs, and complete surveys in minutes, instead of hours. Drones are the smartest option for powerline inspection.

Our industry leaders are thermal imaging drones. Our team of experts is a pioneer in thermal drone technology and will help you create a customized solution that suits your needs and budget.

After the inspection is complete, the drone operator can begin the photos collection, image uploading, defect analysis, and report generation. It can then submit a summary line inspection report to the grid operator.

Flash marks, ice coatings, electric current burns, self-explosion and fouling, core rod exposed, damp heat, abnormal discharges, low value or zero value, can all be captured via a drone powerline inspection process.

You can also quickly identify intruding plants that might cause outages and stop them from affecting powerlines.

Thermal Imaging Drone Powerline Inspection

Using our thermal imaging solutions, we can perform additional inspections on your towers, including heat analysis, weak point details, water penetration and trapped moisture analysis, or inspections. Contact us today for more detail on how we provide thermal imaging to help with drone tower inspection services.